CNC Turning Metal Part Factory: The Future of Precision Engineering

In the realm of manufacturing, especially in the area of metal fabrication, the term “CNC turning metal part factory” signifies a powerhouse of innovation and efficiency. At DeepMould.net, we pride ourselves on being at the forefront of this technology, providing businesses with high-quality, precision-engineered components designed to meet their specific needs. In this extensive article, we will delve into the intricacies of CNC turning, its benefits, applications, and why choosing the right factory for your metal parts is crucial.

Understanding CNC Turning

CNC turning is a subtractive manufacturing process where material is removed from a rotating workpiece using cutting tools. This method is employed to create cylindrical parts with high precision. The process is primarily controlled by Computer Numerical Control (CNC) technology, which ensures that every component produced within the factory is of consistent quality.

The CNC Turning Process

Here’s an overview of the CNC turning process:

- Design: The process begins with a detailed design, usually created with CAD (Computer-Aided Design) software.

- Programming: The design is translated into a CNC program, which contains precise instructions for the CNC machine.

- Setup: The material is set up on the lathe, and the tools are positioned correctly.

- Turning: The CNC machine starts, rotating the workpiece while cutting tools remove material to achieve the desired shape and dimensions.

- Quality Control: Throughout and after the turning process, quality control measures ensure that the parts meet specifications.

Benefits of CNC Turning in Metal Fabrication

Utilizing a CNC turning metal part factory like DeepMould.net comes with numerous advantages:

- High Precision: CNC turning machines can produce parts with tolerances as tight as +/- 0.001 inches.

- Repeatability: Once a part is programmed into the CNC machine, it can be produced countless times with the same exceptional accuracy.

- Material Versatility: CNC turning can handle a variety of materials, from metals like aluminum and stainless steel to plastics.

- Reduced Waste: The subtractive nature of CNC turning minimizes waste material, making it a cost-effective option.

- Speed: CNC turning significantly reduces production time compared to traditional machining, allowing for quicker turnaround.

Applications of CNC Turning Metal Parts

The versatility of CNC turning makes it applicable in numerous industries, including:

- Aerospace: Precision components for aircraft and spacecraft.

- Automotive: Engine components, shafts, and other machine parts.

- Medical devices: Custom parts for surgical instruments and implants.

- Electronics: Enclosures and connectors for various electronic devices.

Choosing the Right CNC Turning Metal Part Factory

When selecting a CNC turning metal part factory, consider the following factors:

- Experience: Look for a factory with a proven track record in the industry.

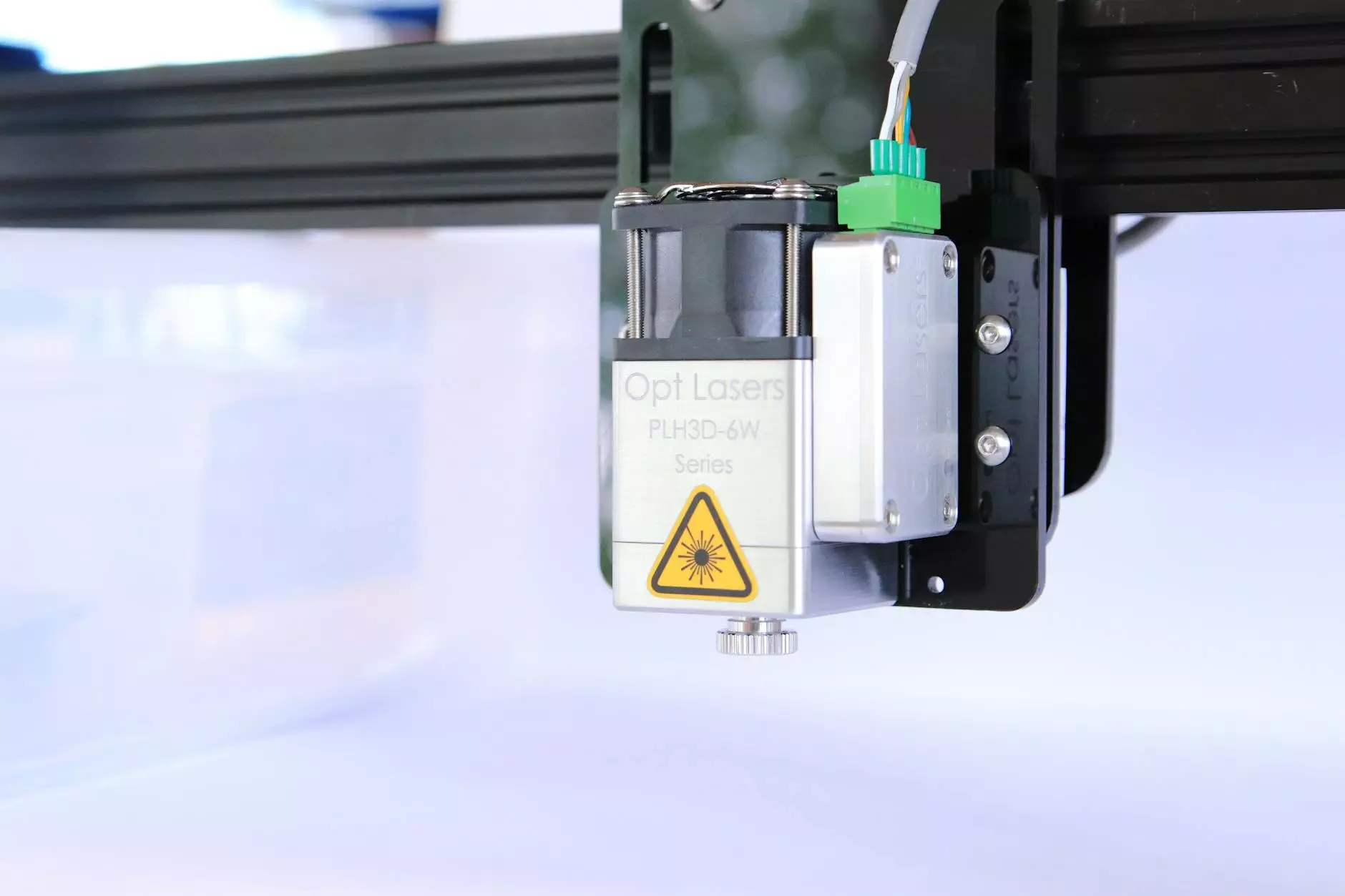

- Technology: Ensure the factory utilizes state-of-the-art CNC machines and software.

- Quality Assurance: A good factory should have a robust quality control process in place.

- Customization: The ability to provide tailor-made solutions for unique applications.

- Customer Support: Responsive and knowledgeable support can make a significant difference.

The Importance of Quality in CNC Turning

Quality cannot be overstated in the manufacturing of CNC turned parts. At DeepMould.net, we implement the following quality assurance practices:

- Initial Inspection: Every batch of raw materials undergoes thorough inspection.

- In-Process Monitoring: Continuous monitoring during the production process to ensure adherence to specifications.

- Final Inspection: Rigorous testing of finished products to guarantee quality.

- Feedback Loop: Gathering feedback from customers to refine and improve processes.

Technological Advances in CNC Turning

The world of CNC turning continues to evolve, significantly enhancing production capabilities and efficiencies:

Integration of IoT

With the internet of things (IoT), CNC machines can be connected to a network, allowing for:

- Remote Monitoring: Operators can track machine performance in real time.

- Predictive Maintenance: Predict potential breakdowns before they occur, minimizing downtime.

Advanced Software Solutions

New software solutions have made programming CNC machines easier and more intuitive:

- Simulations: Allowing designers to visualize the machining process before production begins.

- Automated Toolpath Generation: Enhancing efficiency and reducing lead times.

Environmental Considerations in CNC Turning

As industries move towards sustainable practices, it's essential to consider:\n

- Energy Efficiency: Optimizing machining processes to reduce power consumption.

- Recyclable Materials: Using materials that are recyclable or have minimal environmental impact.

The Future of CNC Turning and Metal Fabrication

Looking ahead, the future of CNC turning metal part factories holds immense potential:

- Automation: Increasing levels of automation will lead to even greater efficiencies.

- Customized Production: The demand for customized products will push factories to adapt and provide unique solutions.

- Global Supply Chain Optimization: Innovations in logistics will enhance delivery times and reduce costs.

- Continuous Learning: Factories that invest in training will lead the way in innovation.

Conclusion

The role of a CNC turning metal part factory like DeepMould.net cannot be underestimated in today's manufacturing landscape. With our commitment to quality, precision, and customer satisfaction, we are well-positioned to meet the evolving needs of various industries. As we advance towards a more automated and connected manufacturing future, embracing these changes and technologies will be key to staying competitive. For all your CNC turning and metal fabrication needs, trust DeepMould.net to provide exceptional service and quality. Your future in precision manufacturing starts here!

Contact Us

For more information about our services and how we can help your business succeed, please visit our website at DeepMould.net or contact us directly.